Inverse Osmosis Services

WHAT IS IT INVERSE OSMOSIS

reverse osmosis equipment works by a water demineralization process through the use of membranes that have a porosity of 0.0001 microns, so they retain ions, reducing the total dissolved solids of the water between 98 to 99%.

This process does not require the use of hazardous chemicals or generate waste that requires treatment since the reject only contains the same salts as the feed water, although more concentrated.

It is possible to adapt the systems according to customer requirements (stainless steel, sanitary piping, instrumentation, steam sanitizers, etc.) in order to meet the necessary quality and operate them efficiently.

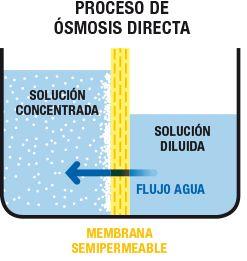

THE PROCESS NATURAL OSMOSIS

When two solutions of different concentration of salts are separated by a semi-permeable membraneIn a natural way, a flow of water is produced from the solution of lower concentration to the one of higher concentration.

This flow continues until the concentrations on both sides of the membrane are equal. This natural phenomenon is known as osmosis. For example:

Fresh water will spontaneously flow through a semi-permeable membrane to mix with a more concentrated solution, such as seawater or brackish water.

When pure water molecules diffuse through the membrane, the pressure on the clean water side decreases, while the pressure on the concentrated solution side increases.

This continues until an equilibrium is reached between the two solutions and the pressure is sufficient to stop the flow. The pressure difference is “presión diferencial osmótica” de las dos soluciones.

Write us to help you and give you more information about: Water treatment systems Equipment Chemical products

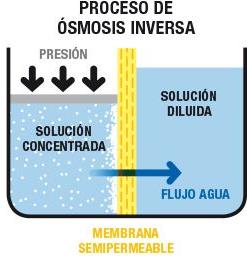

If enough pressure is applied to the concentrated solution (greater than the osmotic differential pressure), the water flow rate is reversed.

Pure water molecules on the concentrated side are forced out through the semi-permeable membrane, and when this happens, salts and other dissolved solids are left behind. In this way pure water is obtained from a concentrated solution.

It is a separation process, there is a difference between the volume of water that enters the system and that which leaves as permeate or "product water". The recovery (amount of pure water recovered from the feed water) can be as low as 30% or as high as 60% or more, depending on the purity level of the feed water.

As a result, the chemical composition of the feed water differs from the final product. (permeado).

THE EQUIPMENT INVERSE OSMOSIS IT HAS TWO FLOWS

Water Flow Rejection

This is the high conductivity water flow (dissolved solids), where the dissolved solids removed from the Product water flow accumulate. As long as the operating conditions are not manipulated or the quality of the feed water is not modified, this flow will remain constant along with the Product water flow.

The reject water flow value is set by the recovery value. This flow may have some minor variations that will not affect the operation of the reverse osmosis equipment as long as the minimum flow is respected.

This flow is directly affected by the manipulation of the pressure regulating valve and the recirculation valve, therefore its manipulation should be avoided unless necessary.

Product Water Flow

This is the flow of low conductivity water (dissolved solids). And a reverse osmosis system must be kept working at a constant product flow rate, unless there is a drastic change in the quality of the feed water.

This flow is indirectly affected by the manipulation of the pressure regulating valve and the recirculation valve (decrease or increase of the operating pressure), therefore its manipulation should be avoided unless necessary.

THE EQUIPMENT OF INVERSE OSMOSIS YOU NEED PERIODIC MAINTENANCE

- NCheck that there are no water leaks in the reverse osmosis equipment.

- NPeriodically check the tightness of the internal electrical connections of the control board, as well as the connection in each external component.

- NCheck current draw of pump motors.

- NCheck the side covers of the membrane holders, verify that the metal locks are not out of position.

Contact us

Escribenos para ayudarte y brindarte más información sobre:

- Water treatment systems

- Equipment

- Quimical products

Our technical advisors will contact you to give you personalized advice.